Product Sustainability

For over 30 years, we’ve been dedicated to providing high-quality and sustainable fiber cement products to the United States and Canada.

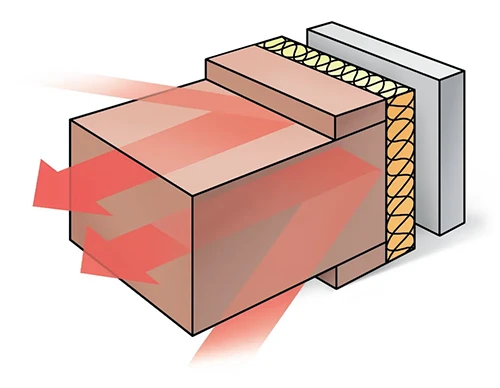

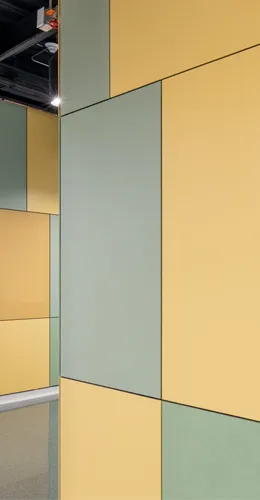

Our fiber cement panels are used to create green (LEED) building projects that benefit the environment. They are built to stand the test of time and rarely require refurbishment or material replacement, reducing a building’s overall maintenance costs. The Ventilated and Insulated Rainscreen Cladding System used to affix panels to facades provides many benefits and green attributes, including resistance to moisture and mold.

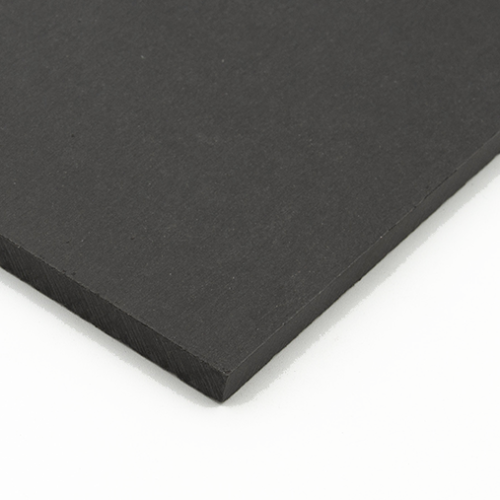

Distinct Properties

American Fiber Cement panels are weather-resistant, low maintenance, non-combustible, and designed to last the lifetime of the building. We install them using an open joint rainscreen system, which allows the panels to adapt to variable weather conditions. We simplify installation by cutting, drilling, and IDing every panel so they can be affixed to your facade immediately upon reaching the job site. By offering easy fabrication and installation, we offer lower installation costs, shorter installation times, minimal maintenance, and a beautifully modern building aesthetic.

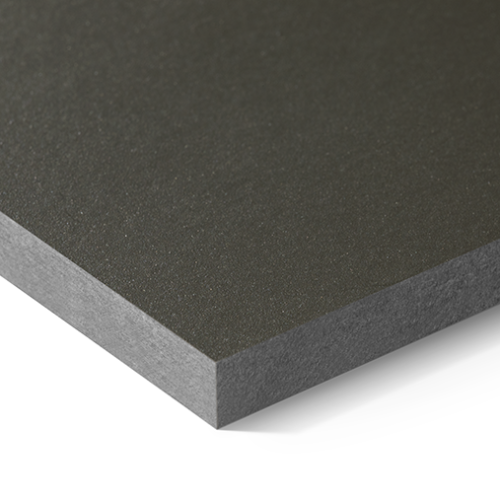

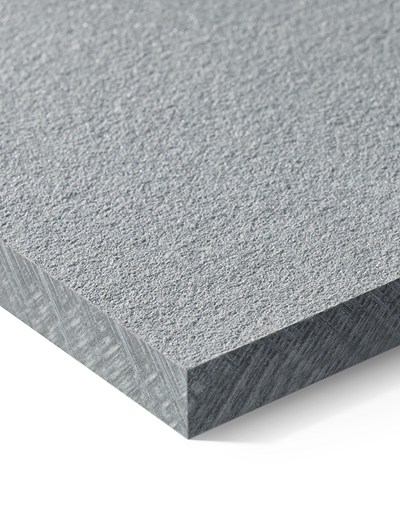

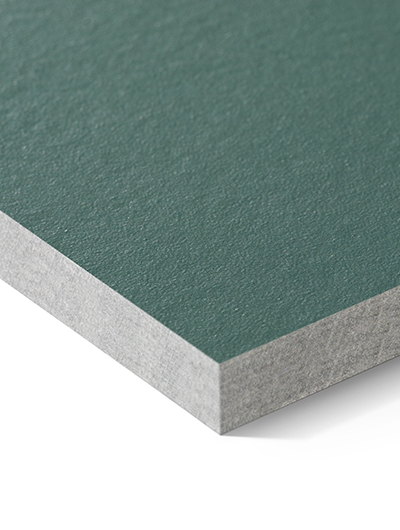

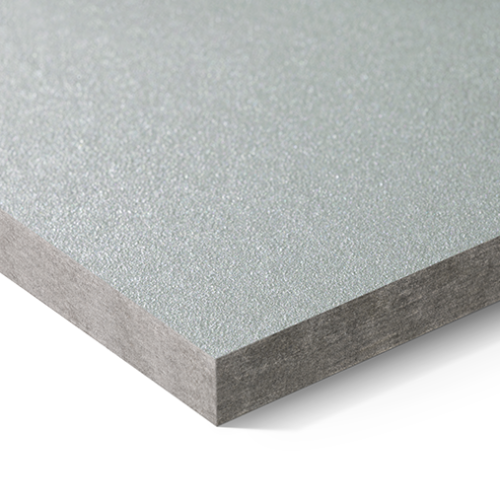

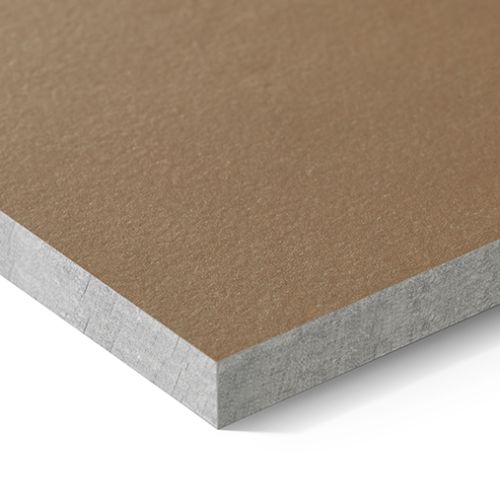

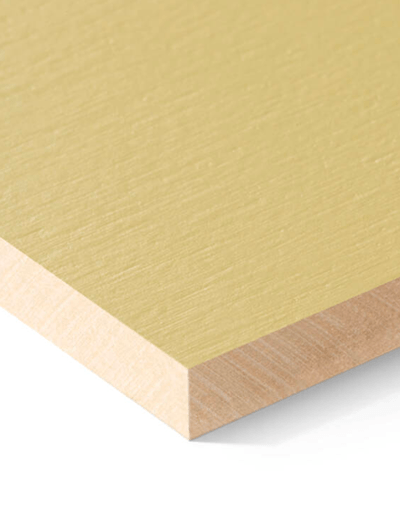

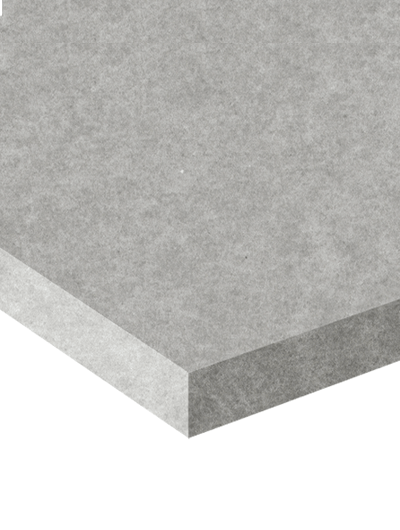

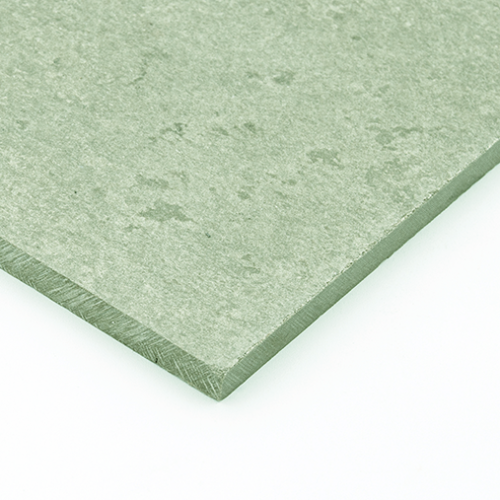

A Unique Composition

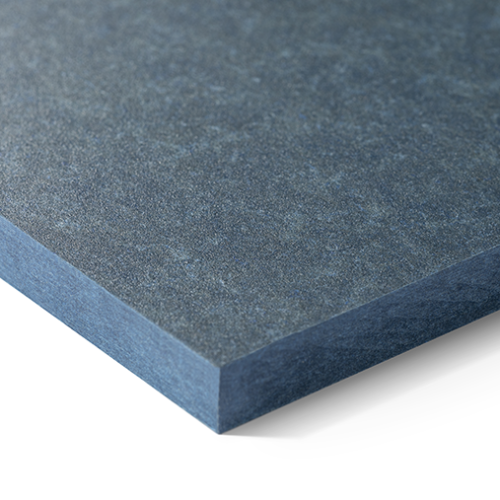

Each panel is made of natural and environmentally friendly raw materials and is fully recyclable. Thin layers of fiber cement are firmly pressed together using tremendous pressure before completing the air-curing process. Carefully selected fibers reinforce the thin layers to create strength and elasticity that is unique to our fiber cement products. Our advanced manufacturing technology ensures every panel delivers impressive strength and remarkable durability.

Leed Credits We Contribute to:

Direct Contribution (Materials and Resources)

BPDO - Environmental Product Declarations

Indirect Contribution

Indoor Environmental Quality

Thermal Comfort

N/A

Energy and Atmosphere

Optimize Energy Performance